The Spectacular Thanksgiving Sailing Weekend

As we closed out the month with a spectacular Thanksgiving weekend, we hope many took advantage of #bluefriday to #optsailing and took some photos for our November Sailagram coming out in the next week or so. There were four beautiful sailing days this past long weekend, so send in a couple of your best shots to [email protected].

These two boats enjoyed Friday’s stunning, though low-wind, conditions.

The monthly Sailagram features shots of California sailors sailing up and down the coast or wherever they might be over the course of the last month. A sampling of snapshots from the current, about-to-be-replaced October Sailagram are featured below.

If you were out this past weekend (or anytime in November) send photos we can include in the November Sailagram to be posted in early December. It’s always great to include boat name, boat type and homeport plus the names of your smiling crew or kangaroo.

Do You Have a California Boater Card?

After last month’s Fleet Week, we received a letter from Capt. Dane Faber of Sausalito, wondering about the California Boater Card and its level of use within the Bay Area.

“Wouldn’t it be a great story to learn the compliance percentage of folks who have actually gotten one?” Dane wrote.

We shared the news of the card’s imminent introduction in December 2017.

“Signed into law in 2014, the Boater ID Law will begin phasing in by requiring boaters 20 years of age and younger to have the new Boater Card. Each new year, a new age group will be added until 2025, when all persons who operate a motorized vessel on California waters will be required to have one. (Motorized vessels include sailboats with any sort of engine on them. Do you have an Opti with an outboard on it? Then you would technically be considered a ‘motorized vessel’ and subject to the card requirement when your age group is phased in.)”

The table below is shown on the California Boater Card website, under FAQ:

As of the dates shown below, these boaters will be required to carry a boater card issued by DBW, unless they meet certain exemptions.

California Harbors and Navigation Code Section 678.11(b) contains the following phase-in schedule based on operator age:

- January 1, 2018 Persons 20 years of age or younger

- January 1, 2019 Persons 25 years of age or younger

- January 1, 2020 Persons 35 years of age or younger

- January 1, 2021 Persons 40 years of age or younger

- January 1, 2022 Persons 45 years of age or younger

- January 1, 2023 Persons 50 years of age or younger

- January 1, 2024 Persons 60 years of age or younger

- January 1, 2025 All persons regardless of age

At the time of our writing, it wasn’t clear how enforcement of the card would work, or what type of boaters it would target — “Will high-powered motor boats be more heavily scrutinized than sailboats, or will enforcement be equal across all boat types?”

It seems perhaps these and other questions are still unanswered.

“Listening to VHF 16 today (7 Oct) ahead of air show,” Dane continued, “leads me to think very few have bothered, and those who may have acquired it sail with impunity anyway.”

We imagine this comment was inspired by the various boating skills in action during events such as Fleet Week. Seasoned skippers know to look out for boaters who have either no idea of the rules, or no regard for them.

Our questions for today are, “Do you have a California Boater Card?” And, “Have you ever been required to show your California Boater Card?”

Celebrate the Holidays In Style Aboard Hotel California

Book your holiday charter today. Call (415) 747-4733 or visit www.liveitupcharter.com for more information.

The Resourceful Sailor Performs Sail Surgery

Last week, while preparing our boat to sail for the first time since we began its refit nearly three years ago, we were rethreading the jib into its track when we heard a ripping sound. A quick look showed the main part of the sail to be intact. “No problem,” one thought, while the other knew better. A ripping sound is only produced by the action of ripping. And so, there it was, a small 3/4-inch tear in the luff. It reminded us of this DIY sail repair by The Resourceful Sailor.

After an exciting beat into Port Angeles Harbor under three reefs and the 80% jib, with building thermal, The Resourceful Sailor reached the western lee of the breakwater aboard Sampaguita, a 1985 Pacific Seacraft Flicka 20. Upon starting the outboard and lowering sail for the approach to the Customs dock in the local marina, the leech line of the jib was discovered partially extracted from the sail and wrapped around the starboard sheet. The best guess was that when the sail was violently flogging on the tacks, the tail wrapped around the sheet. The sheet then came under heavy load, and the tension on the leech line was enough to break it free from the anchor stitching at the head of the sail. Questions of repair were now afoot.

Do I take the sail to a sailmaker? How would a sailmaker repair it? What if a sailmaker was unavailable? How would The Resourceful Sailor fix it? A search for online videos found one on building a leech line into a sail and another on replacing it for a repair. In both instances, they laid the leech line down, sewing the pocket around it. While neither of these was precisely the situation, they gave some insight.

The jib was still in good condition, as was the leech line pocket. To completely disassemble the leech pocket and start from scratch seemed excessive. It would also be much easier with a proper sewing machine, which I did not have. Alternatively, the leech line might be re-inserted into the existing leech pocket and reattached at the head. While this could also be a sailmaker’s choice, it was one I could do on my own.

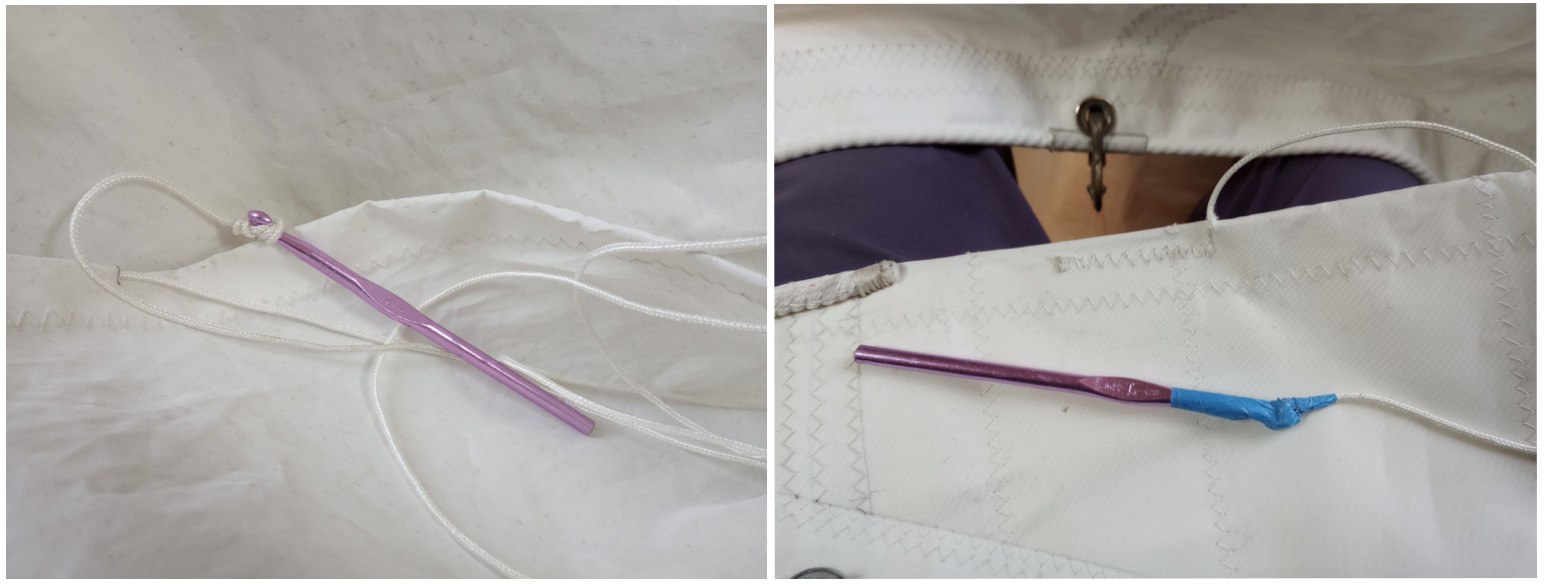

DIY re-insertion would be the way. The first question was whether to fully extract the line and start from the bottom (the line was at about the midpoint) or begin from where it was. Starting mid-sail would require an incision to retrieve the line end and add a rigid tool for working it through the pocket (like the drawstring on a hoodie or sweatpants). It would also mean a sail repair at this spot. Fully extracting the line first and starting from the bottom would avoid that, but with lack of experience, there was uncertainty on how easy rethreading the line through the stiff Dacron pocket the entire length of the sail would be. Either way, there would also need to be an incision at the head of the sail as an exit point for the threading tool and to be able to manipulate the leech line with the proper loop into its anchor spot for stitching.

Choosing to start “as-was,” I made a small incision just big enough for the line extraction and the rigid threading tool, a crochet hook, to be inserted. The line and hook were securely taped together, inserted, and pushed to the head of the sail and the exit incision to draw the line through and remove the tool. In hindsight, this was reasonably easy, and the choice to fully extract the line to avoid the mid-pocket sail repair may have been the better option.

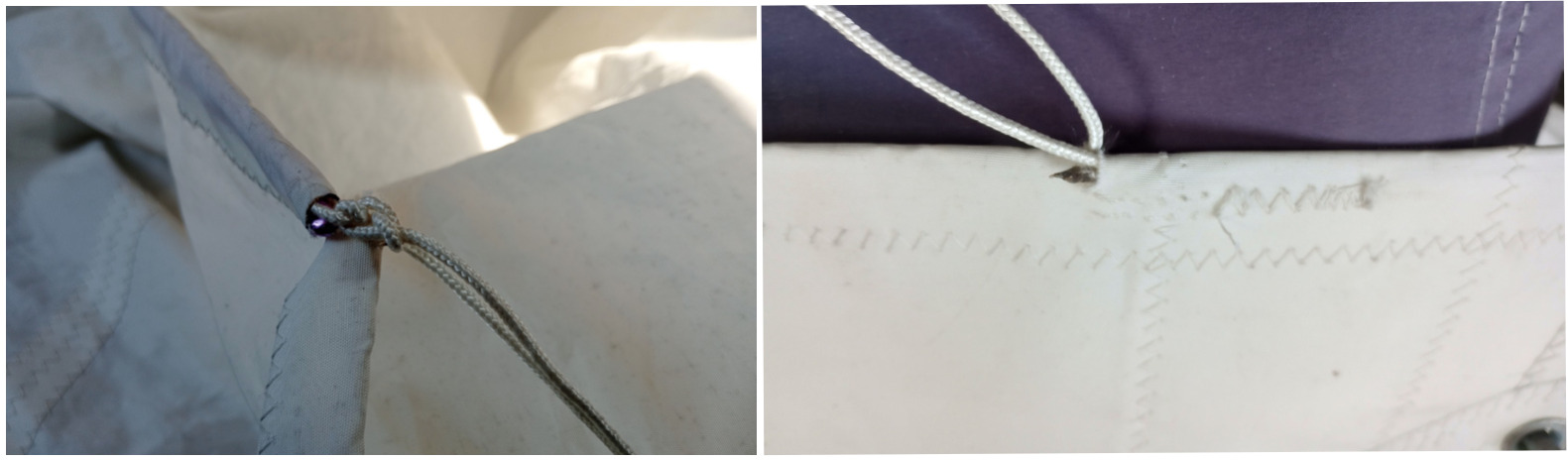

The leech line had come free from the stitching rather than breaking. The online videos showed the leech line looped and heavily stitched at the head. It was impossible to tell if this one had been or not. Or whether the subsequent stitching had been thorough. Maybe it was designed to be a weak link to prevent sail tear? The videos did express how the multiple layers of sailcloth in the head were a challenge for even a sailmaker sewing machine.

The line was looped and re-inserted through the incision and worked into position alongside the old anchor stitching using an uncoiled paper clip. I then applied new anchor stitching using a sewing palm, a sailmaker needle, and Dacron thread. If the multiple cloth layers were challenging for a hardy sewing machine, you can bet they were especially so by hand. While easier to bend and break, a thinner, long-pointed needle was the best approach to penetrate the cloth. A larger needle would have been stronger, but the resistance of its diameter was too high. The resultant anchor stitch would not win any best-dressed-yachtie awards, but I was confident that it captured the leech line and would do the required job as well as (hopefully better than) the original.

Both incisions received the same repair. First, the cut edges were carefully hot-knifed to seal them to prevent fraying. A small piece of folded sailcloth in those spots over the leech covered both sides of the incisions, with a larger patch of sticky-backed sail tape put over the top of this. Both were hand-stitched along the edges, bringing the integrity of the leech line pocket back to the pre-incision level. The layered head was again the most tedious part, while the mid-leech repair through single and double layers was relatively easy. There was a marked improvement in stitching quality, both as time progressed and with fewer cloth layers.

The Resourceful Sailor is still unsure what a sailmaker’s approach to this repair would be. Boatyard experience has taught “Ask three different tradesmen, get five different answers.” They are satisfied with the result and the knowledge acquired in the process. A sailmaker will not always be available, and DIY is The Resourceful Sailor way. Sampaguita keeps sail repair supplies on board, not for if they are needed, but for when they are.

Remember, keep your solutions safe and prudent, and have a blast.

The Radical Uniqueness of ‘Rosie G’

There are many things you might be curious about if you cross tacks with the maroon, junk-rigged, 42-ft scow-bowed, Jim Antrim-designed cruising boat Rosie G. You might wonder who WAG sailmakers are when you notice the logo on the sail, or note her silence if she motors by, or be concerned there’s no cooling water coming from her exhaust. You might also wonder, “What’s up with that bow?”

These are all good questions that can be answered by Rosie G’s creator, Barry Spanier, and his wife Samantha, who have been out refining their new creation, launched several months ago after she was built at Berkeley Marine Center.

Rosie G was designed by local legend Jim Antrim, but many of her architectural design elements fall under the “WAG” concept, which in the designer milieu is an acronym for “Wild-Ass Guess.” In an era of CAD/CAM, AI and algorithms there are still plenty of variables and personal preferences when it comes to creating something unique. Barry’s creative perspectives are what made him a successful and sought-after windsurfing sail designer for decades. Now, shifting gears, he’s poured his alternative creative ideas into a unique concept for cruising boats.

Of course, neither junk-rigged boats nor scow bows are new. Junk rigs were pioneered in Asia centuries ago and applied to modern use by Blondie Hasler, who sailed a junk-rigged Folkboat across the Atlantic in the Singlehanded Transatlantic race in the ’60s. Scow-bowed boats are popular in the Great Lakes, the lumber schooner Alma, and the revolutionary scow-bowed 21-footers that have also been winning the Mini Transat transatlantic race for years. (Spanier has said that modern America’s Cup foiling monohulls have what are essentially scow bows, which keep the boats’ noses from digging when they slam into the water off their foils.)

A curious, inventive creator like Barry thought it could make sense to combine the simplicity of a junk rig with the performance and interior volume of a scow-bowed cruiser, aided by the refinement of a noted naval architect like Antrim to come up with a visionary 42-ft cruiser. Our sail aboard Rosie G confirmed there’s still lots of room for restless minds to evolve the concept of cruising sailboats. A pleasant Sunday sail demonstrated more of the intricate, unique details such as a quiet Electric Yacht auxiliary and lithium batteries with lots of power available from Sunpower solar panels covering ample real estate atop a broad pilothouse.

The pilothouse itself allows for 360-degree views from the interior, and the ample beam allows the cruising sailmaker to have a dining table that also houses a sewing machine right in the main salon. A composting head minimizes thru-hulls and eliminates hoses and holding tanks. The electric drive means there are no tanks on board for fuel. And hydroponic growing pots allow for vegetables to be grown on board.

Read more in the November issue of Latitude 38.