A Latitude Far, Far Away

In honor of the release of Star Wars, Episode VIII today, we wanted to share a story from Howard Macken of Sutter Sails, who wrote the following for the September 1983 (Vol. 75) issue of Latitude 38. It’s easy to forget that Star Wars has its roots in Marin County, and, for one movie, employed a bevy of notable Bay Area sailors.

It was 2 a.m., the wind was blowing a good 25 or 30 mph as I stood on the poop deck looking forward. The men on the deck below were working furiously bending and furling the massive brown sails. The vision conjured was that of a Spanish galleon running before a squall. But instead of spray stunning our faces, it was sand. Sand in our mouths and sand in our hair. The ocean on the far, far horizon was not water, but desert. There were sand dunes as far as the eye could see on this moonlit night.

Well, actually it was. We were on the deck of Jabba’s Barge, 100 feet above the desert floor, on the planet of Tatooine.

It all started back in February 1982, when I stopped by Bill Kreysler’s new shop in San Rafael. Since the demise of Performance Sailcraft (which used to make Lasers and J/24s), Bill had taken over some of their space and was doing custom fiberglass and mold work. He’d just signed a contract to build some fiberglass panels for Revenge of the Jedi (later named Return of the Jedi). I jokingly asked if they needed any sewing done, and Bill said they were building some kind of barge in the sand dunes near Yuma, and that they might need some sails.

I didn’t take it too seriously until two weeks later when I received a call from Commodore [Warwick] Tompkins, asking to meet with me and discuss the Lucasfilm project. Actually, there were three of us at that first meeting: me, Commodore and Derek Baylis, a well-known local yachtsman and a consulting engineer. They were both excited over the proposal from Lucasfilm. Bill was in charge of organizing the construction of the mast, spars and sails for Jabba’s Barge, which would be one of the largest, most elaborate sets for Return of the Jedi.

And we at Sutter Sails . . . would build the sails.

In March, we had about a month to design the sails and ship them to Yuma. Luckily it was our off-time at the loft, and we devoted our full attention to the project. Six hundred yards of tanbark material was ordered from Walter Crump of Aquino Sailcloth.

The actual rig was to resemble a "Regalo schooner," with the two Regalo sails overlapped with the mast and kingspar higher than the fore. Each of the four sails had seven full-length battens totaling 250 feet. The longest were two-inch- square aluminum extrusions, and the rest were inch-and-a-half pultruded fiberglass.

The kingspars were ordered from Sparcraft, who had the largest sections available on the West Coast: a 14" oval by 70′ long. These were then tapered down at each end to 4". Victor Iron Works of San Rafael did the welding on the sqaure masts. Derek had devised a system whereby the whole rig would lower when not in use and raise when the sails were out and filming was in progress.

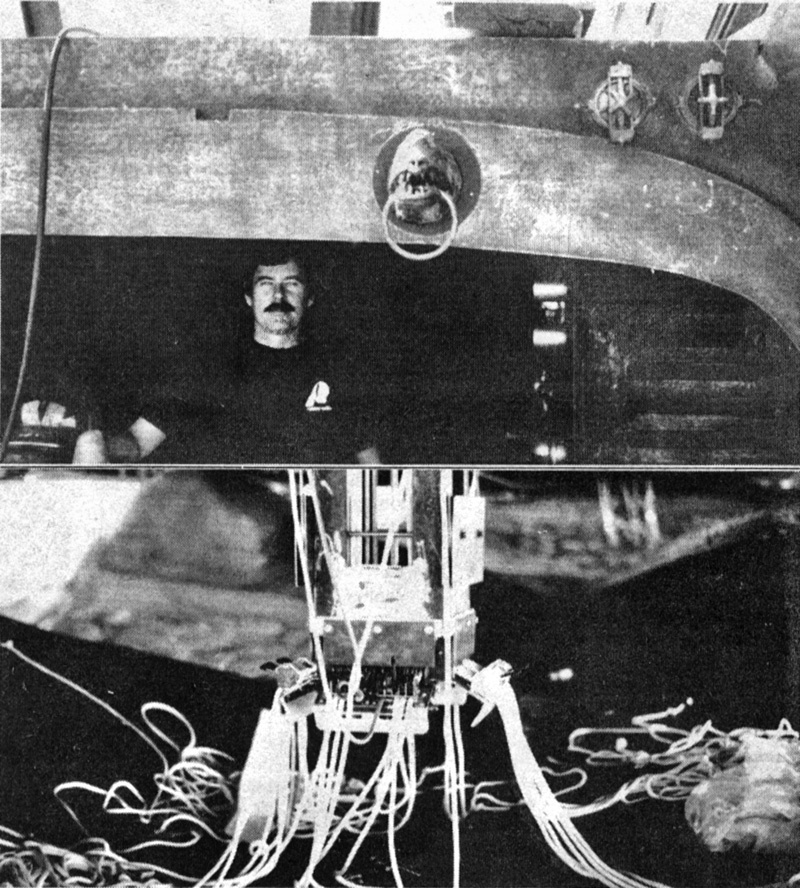

The act of raising and lowering the mast, and the "brailing" or furling of the sail, would be carried out deep in the bilge. At the base of each mast was a battery of sheet jammers, winches and blocks, not unlike many of the 12-Meters of the 1970s.

©2017Latitude 38 Media, LLC

All through March, our seamstresses Terry, Peggy and Sandra were busy at a yeoman’s (yeowoman’s?) job of stuffing all that heavy sailcloth through the sewing machines. The sails were all seamed and the batten pockets installed at the loft. But the sails had to be finished when the "clew" locations were known. This would be done on location in Yuma. Peggy Kashuba and I drove down to Yuma late in March with two machines, the sails, equipment and extra sail cloth. Louis Friedman, the unit supervisor at Lucasfilm, had set us up with a vacant dance studio to use as a makeshift loft. Sutter Sails Southwest was in business!

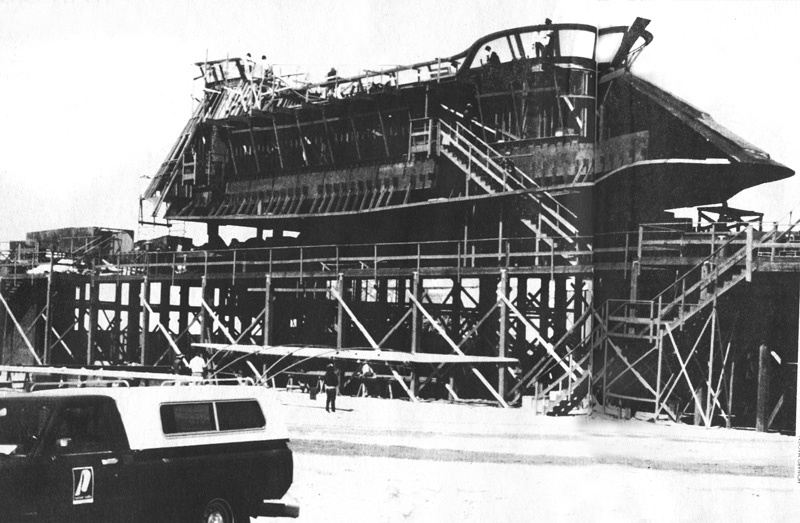

Seeing the set for the first time was a big thrill. The barge was an incredible piece of work (a cross between a galleon and the space shuttle). It was "hovering" beside the Sarlacc Pit, which didn’t frighten us at all: Indeed, we found it to be the coolest spot within a 50-mile radius for eating lunch.

We had the clew locations and began our marathon sessions behind the sewing machines. Bill, Derek and Commodore were all at the site trying to install the spar masts and rigging amidst the carpenters, painters, electricians and the ever-present art directors, who could decide to change everything at a moment’s notice.

Bending the sails was no easy task. The problem was the installation of the battens, which had to be put in the sails in two pieces, and then tensioned and bolted. All of this had to be done with the wind blowing, and with the rig high enough off the deck to make working very awkward.

©2017Latitude 38 Media, LLC

Commodore was in his element here, hanging in the bosun’s chair from a huge crane, directing the whole operation. When it was time to set the sails, we radioed instructions to the crew in the bilge and the huge sails were sheeted home. The aft two sails were set first, and with the wind increasing all the time, the decision was made to go for broke and set all the sails. An anemometer was rigged up on the aft kingspar and read in the bilge, then radioed on deck (it was blowing 20 to 25). Gusts could easily be seen approaching as large clouds of sand appeared on the horizon from a good mile away.

We all just stood there on deck, listening to the wind howling. We were waiting for something to give (it was now gusting to 35), but lo and behold, everything was as stable as a rock. Derek had done himself proud. My nightmares of the sails coming apart during filming were fading away.

It was now just three days away before shooting started, and we were finished. It was a great feeling for our crew of Bay Area sailors. We’d pulled it off in record time and done a first-class job to boot. Bill, Derek and I returned home with mixed emotions. It was good to be home and get some rest, but it had been an exciting two weeks, and we were sorry to miss filming.

Commodore and Peggy stayed with the Lucasfilm crew. Commodore supervised the furling and unfurling of the sails each day, and Peggy stayed in case my nightmare came true and emergency repairs had to be made.

It was an experience that none of us will ever forget It was thrilling to be involved, and to see first hand how it all came together to produce a movie. But working with the Lucasfilm people made it extra special. Their reputation in working with local businesses was affirmed and appreciated. They were dedicated crew who insisted on doing the job right with no compromises. We felt proud to have played a small part in their efforts.

This story has been edited from the original version.